Avoid manual entry errors

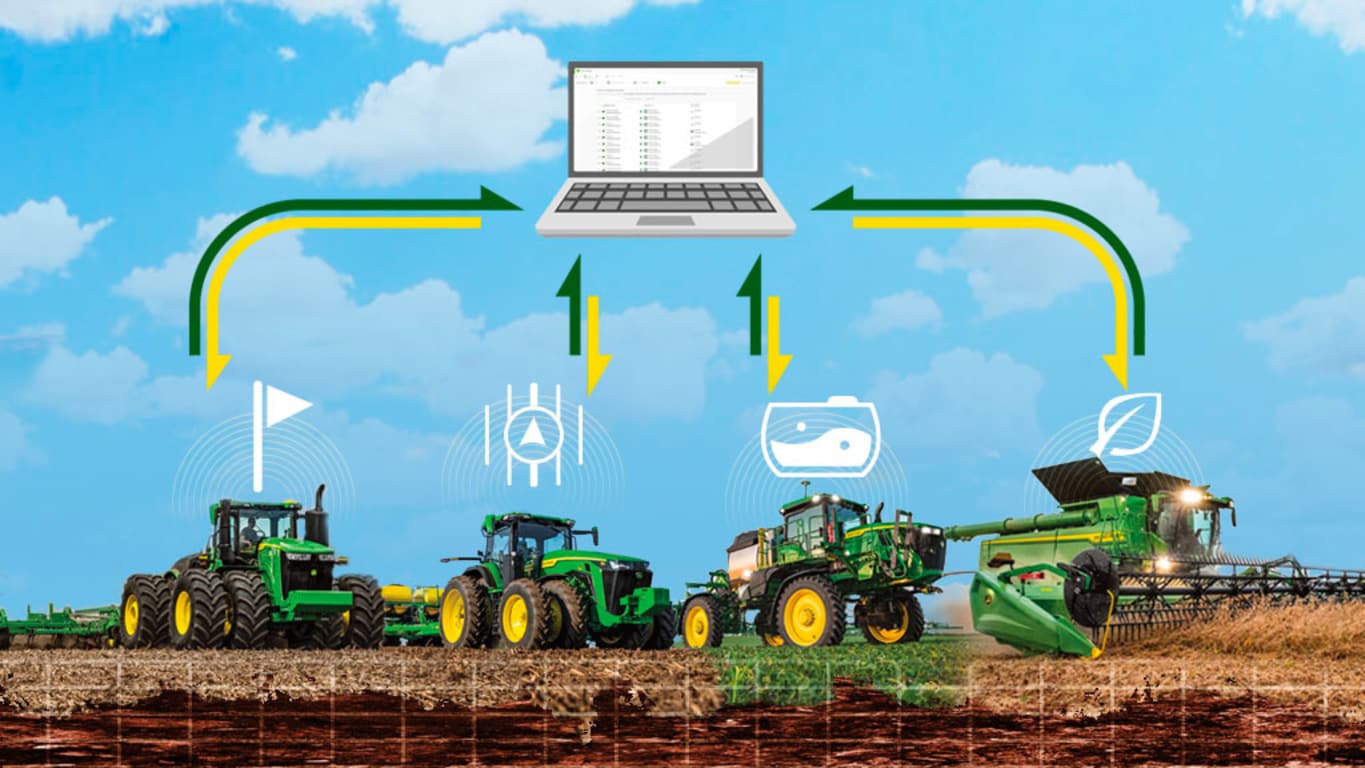

Syncing active setup information from John Deere Operations Center to Data Sync Setup-enabled displays removes manual entry that can cause duplicate or incorrect information to be created throughout the season. Increase confidence in work data collected during tillage, application, planting, and harvest by leveraging one common setup list when planning and starting work. This will help ensure that documentation data will be accurate for analysis and remote management. Having accurate implements, fields, products, tank mixes, and operators drives the intended results for field operation and the ability to make more educated decisions using Operations Center Analyze tools.

Less chance of duplication and spelling errors. By automating the steps to share setup data and working from one aligned setup list, a farming operation can improve their ability to select the correct data and save time getting set up in the field.

Increase accuracy and save time through seamless alignment of implement information

Accurate implement profiles are essential for the success of many precision technology solutions – AutoPath™, AutoTrac™ Turn Automation, Section Control, work documentation, or even boundary recording. The accuracy of technology relies on exact equipment measurements to refine the work being completed or overall performance can suffer. Using Data Sync Setup to seamlessly sync implement information and characteristics ensures that the same up to date profile exists on enabled displays and within Operations Center. Edits made will also sync, keeping the information aligned following the import options established by the organization.

Syncing implements will alleviate the need to create implement profiles multiple times across different machines that use the same implement during the year. It also reduces the risk of entering a mistaken measurement when moving machine to machine. Leverage data cleanup tools available in Operations Center Equipment to Merge, Archive, Filter, and Manage Columns to ensure the information remains accurate and up to date as it syncs to the fleet.

Implement profile created in either the display or Operations Center which will sync through Data Sync Setup

Improve efficiency and reduce steps by syncing guidance lines

Guidance lines created in one operation are often needed by the next in a short time window. Data Sync Setup removes steps required to manually send guidance lines to the fleet. Gain access to straight tracks, curve tracks, and circle tracks in near real time after the guidance line has been created.

Share on-the-go changes

Add flags for specific areas, points, or lines in season, knowing that operators will remain notified about what to pay special attention to or avoid. Add any notes on the go tied to additional field work needed for that flag such as repairing a damaged tile lines or pre-season cleanup. New flags, edits to existing flags, or even deletions of flags will sync to and from Operations Center and other Data Sync Setup enabled displays in near real time.

Add a variety in season that may not have been planned for or was not originally made available at the beginning of the season. Make it available and feel confident knowing the other machines will also have that variety in their drop-down list for use and available for accurate data recording.

Make product or tank mix adjustments on the fly, ensuring that those changes are updated across all Data Sync Setup enabled displays in the organization. One shared setup list available for all within a connected organization and reflected in Operations Center.